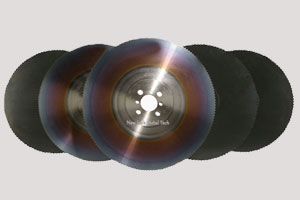

HSS Cold Saw Blades

COLD SAW

Metaltech offers a extensive range of finest quality Cold saw to our clients. Recently Metaltech have collaboration with the GLG Spain. (Barcelona). We are the sole distributor of the GLG cold saw blades in whole India and some countries of Middle East Asia and Gulf. We promise to provide high end quality blades. The main advantage of cutting with cold saw is blade and material being cut remains cold and a cold saw cut produces minimal burr, no sparks, no discoloration and no dust. The material being cut must be mechanically clamped to prevent movement during the cutting process. Cold saws are capable of machining most ferrous and non-ferrous alloys. Cold saws are intended to be used with a flood coolant system to keep the saw blade teeth cooled and lubricated. Appropriate numbers of teeth, saw blade type, cutting speed and feed rate all of these variables are based on the type and size of material being cut.

CUTTING OPERATION

Cold saw blades are used to cut metal using a relatively slow rotational speed, usually less than 5000 surface feet per minute (SFM) (25m/s), and a high chip load per tooth, usually between .001" - .003" (0.025 - 0.08mm) per tooth. These blades are driven by a high power motor and high-torque gear reduction unit or an AC vector drive. During the cutting process, the metal is released in a shearing action by the teeth as the blade turns and the feed mechanism moves the blade forward. They are called "cold saw blades" because they transfer all the energy and heat created during the cutting process to the chip. This enables the blade and the work material to remain cold.

Other customer specified special friction saw blades are available to order.

Portable saws

These saws were primarily designed for sheet metal roofers in the building industry,

and can cut up to 6 mm (0.24 in) thick mild steel. Cold saws, as opposed to abrasive saws,

are used so that protective coating is not damaged. They have a heavy duty aluminium catcher which

is useful for capturing the swarf, and use cermet tipped blades.

Blades

Cold saw blades are circular metal cutting saw blades categorized into two types:

solid HSS or tungsten carbide-tipped (TCT). Both types of blades are resharpenable and may be used

many times before being discarded. Cold saw blades are used to cut metal using a relatively

slow rotational speed, usually less than 5000 surface feet per minute (SFM) (25m/s),

and a high chip load per tooth, usually between .001" - .003" (0.025 - 0.08mm) per tooth.

These blades are driven by a high power motor and high-torque gear reduction unit or an AC vector drive.

During the cutting process, the metal is released in a shearing action by the teeth as the blade turns

and the feed mechanism moves the blade forward. They are called "cold saw blades" because they transfer

all the energy and heat created during the cutting process to the chip. This enables the blade

and the work material to remain cold.

Classification

The first type of cold saw blade, solid HSS, may be made from either M2 tool steel or M35 tool steel,

alloyed with additional cobalt. Solid HSS saw blades are heat treated and hardened to 64/65 HRC for ferrous

cutting applications and 58/60 HRC for non-ferrous cutting applications. This high hardness gives the cutting

edges of the teeth a high resistance to heat and wear. However, this increased hardness also makes

the blades brittle and not very resistant to shock. In order to produce a high quality HSS cold saw blade,

you must start with very flat and properly tensioned raw material. The blades must be press quenched after

hardening to prevent them from being warped. HSS saw blades are typically hollow ground for clearance

during the cutting process. The term HSS doesn't necessarily mean what it implies.

These blades are usually never run at surface speeds higher than 350 SFM. Solid HSS cold saw blades may

be used for cutting many different shapes and types of metal including: tubes, extrusions, structural sections,

billets, bars, ingots, castings, forgings etc. These blades may also be coated with special wear resistant

coatings such as titanium nitride (TiN) or titanium aluminum nitride (TiAlN),

but are more commonly used commercially with a black Oxide coating aiding in better coolant distribution

over the surface area of the cutting blade.